Tel.: +86 13358378970

E-mail: sales6@saulplc.com

Tel.: +86 13358378970

E-mail: sales6@saulplc.com

Jun. 14, 2023

Data, as a key element in the development of industry towards intelligent manufacturing, plays an increasingly important role in the upgrading practice of enterprises. Delta always takes it as its responsibility to provide customers with complete automation solutions, continuously strengthening the industrial automation product series, and helping industry users' solution integration capabilities to a new level.

In response to the increasing demand for precision machining, Delta has integrated advanced technology and industry development experience to launch the laser displacement sensor LD-E series, achieving precise geometric measurement.

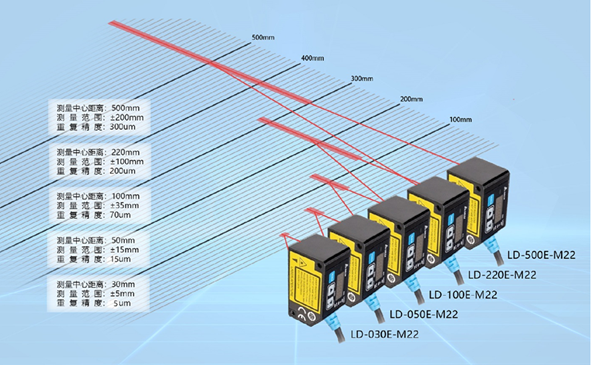

01 Wide ranging with high accuracy to meet more usage needs

The LD-E series of laser displacement sensors includes five models, with a detection range of 25mm to 700mm, and can be flexibly selected according to the different needs of users. In addition, LD-E also performs well in measurement accuracy, with a repeatability accuracy as low as 5 μ m. The linearity can reach ± 0.1% F.S, which can meet the accuracy requirements of most usage environments.

02 supports multiple modes of visible measurement results

The LD-E series of laser displacement sensors supports two output types: NPN/PNP, and users can switch freely according to their own needs; Supports Modbus RS-485 communication function, further expanding the product's usage range; Equipped with 4-20mA analog current output, the measurement results are displayed clearly.

03 Diversified teaching methods, intelligent output of measurement results

The LD-E series of laser displacement sensors is an intelligent sensor equipped with four teaching methods. Users only need to make simple settings, and the sensor can automatically judge the results of the measured items based on the measured values, thereby achieving rapid identification, classification, and other purposes.

Based on the powerful performance of the LD-E series, it can be applied to measure the thickness and width of objects, judge height, gradient, position, flatness, gap and distance, and yaw.

Size detection: used for woodworking cutting machines to measure the thickness and size of wooden boards in conjunction with actual mechanical actions, and feed back the data to the upper computer, and enter energy-saving standby mode during transportation.

Horizontal correction: used for photocuring 3D printers, to measure the height of forming materials in real-time to assist in horizontal correction, greatly improving the printing accuracy of the model.

Flatness detection: used for automotive equipment, using multiple laser sensors to simultaneously measure the positions of different points of the inspected workpiece, and determine whether the flatness of the workpiece meets the standard by the distance difference between the corresponding points.

Safe distance detection: used for wind power generation equipment to detect the position of the wind blades and generator in real-time during the operation of the wind turbine, and determine whether the position of the wind blades exceeds the safe distance.

Deformation detection: used on public sanitation vehicles to measure the deformation of the bottom buffer plate of the garbage truck and detect the load of the vehicle in real time, making the vehicle operation more stable.

Delta intelligent sensors have become reliable assistants for industrial customers in many industries. We believe that with the new generation of laser displacement sensor LD-E series products, we can provide greater assistance for customers on their path of automation and intelligence upgrade!

Navigation

Add.: 9D, 9th Floor, Huguang Building, Hubin West Road, Siming District, Xiamen City, Fujian Province, China

Tel.: +86 13358378970

Mob.: +86 13358378970

E-mail: sales6@saulplc.com

WhatsApp: +86 13358378970

Wechat: +86 13358378970